Visiting Chord Electronics HQ

CHORD ELECTRONICS THE WORKS CREATIVE HUB AND FACTORY VISIT

Chord Electronics invited us to an exclusive press day and revealed their new building, “The Works”, a brand-new creative hub next door to their manufacturing premises.

Chord Electronics is based just outside Maidstone, Kent, in the South East of the UK. Their roots are in the aviation world, where “engineering without limits means uncompromising standards”. This concept, from company owner John Franks, has helped shape Chord’s philosophy since the company’s inception in 1989. Their first amplifiers were supplied to the BBC, followed by world-leading studios including Abbey Road, Sony Music (New York) and later, The Royal Opera House. Their reputation in the professional world generated demand for a domestic range from Chord, and today, they apply proprietary technologies to all of their British-made products.

VISITING CHORD ELECTRONICS HQ

After coffee and refreshments, we were given an intro to the brand by MD Matt Bartlett, who has been working for the company since 1990, and a short intro to the professional side of the business by Tom. He recounted a recent situation where Abbey Road called on a Wednesday evening and required 6 monoblock amplifiers in New York for a Disney film score recording, by the Friday. Sure enough, the team managed to pull off this extraordinary feat, showing their commitment to helping those in need within the pro-audio industry.

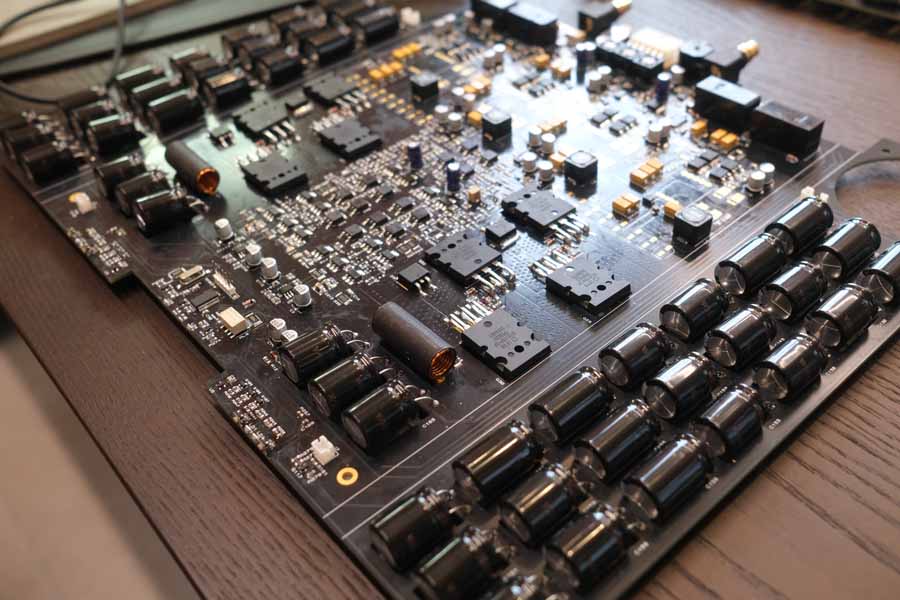

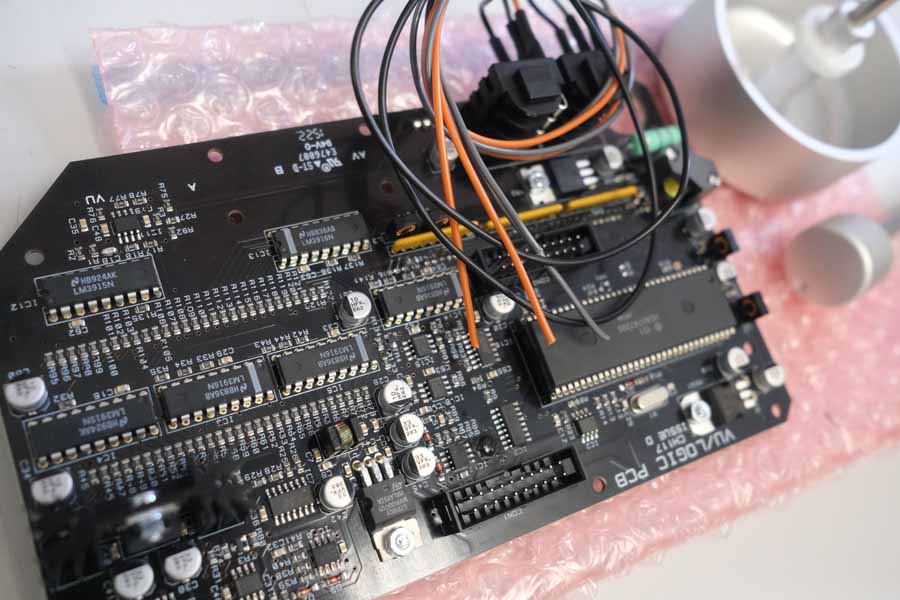

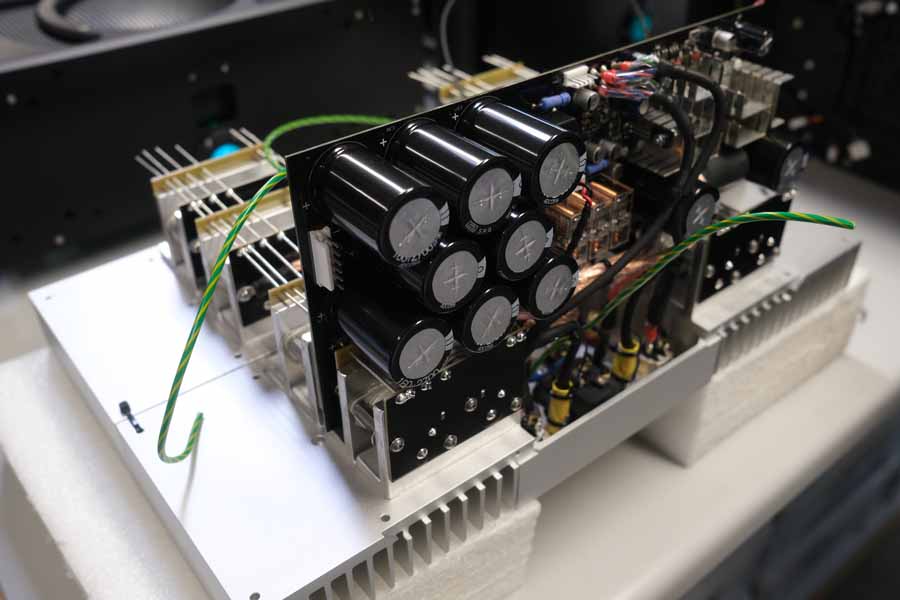

Chord Electronics have a strong background in pro-audio, having made amplifiers for studios for many years now, and this knowledge feeds back into the HiFi world, where clarity and precision can help you get the most out of your system. In this room they had a range of their older legacy products, alongside new production kit such as the Ultima mono, with a range of different speakers to test them with.

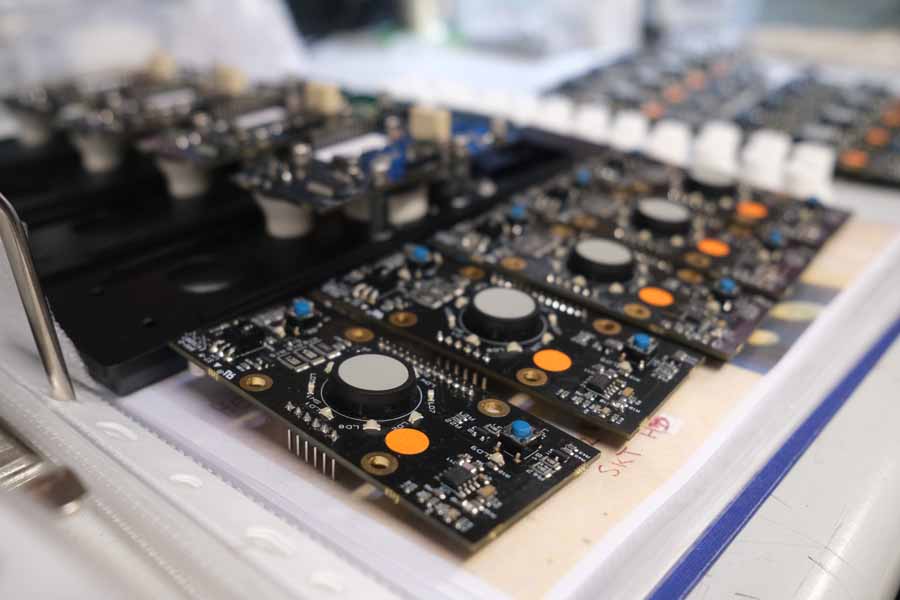

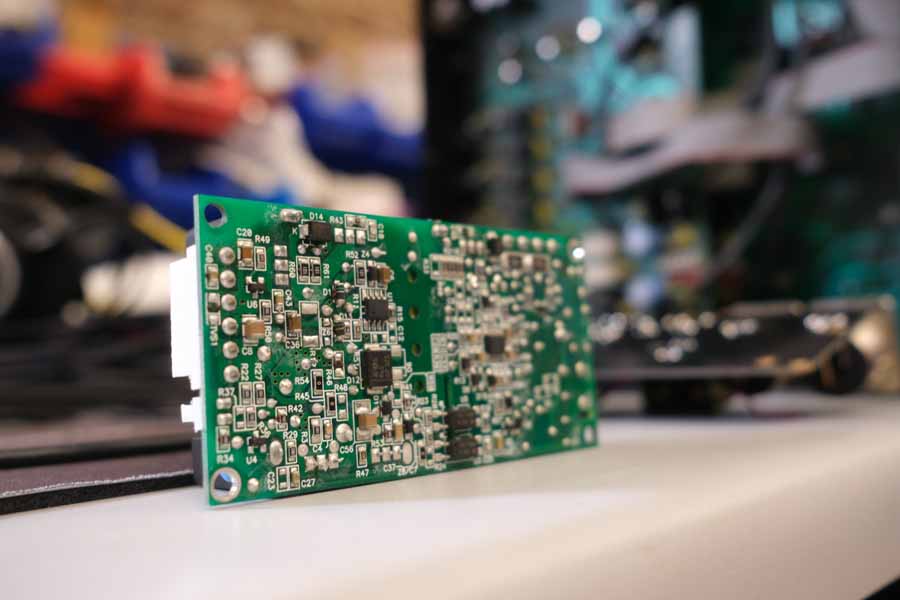

After this short intro, we had a quick tour around their main building, we got to see the new service area, the manufacturing floor, and logistics side of things. Chord Electronics assemble all the products in-house, and many of the components are sourced locally or within the UK.

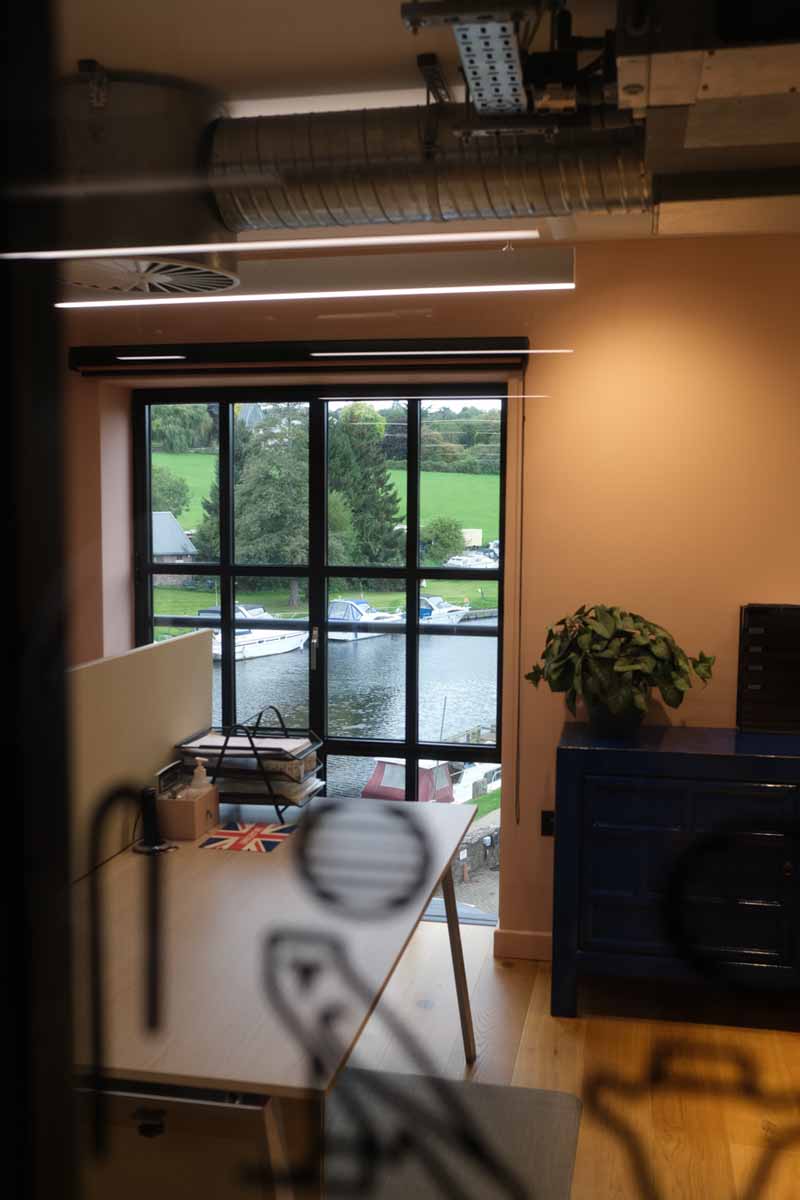

THE WORKS

After looking around their main building, we were taken over the road to their brand new “The Works” premises – a Grade II listed building they have fully renovated to house their office spaces. This is a bright and open space with offices. The original building was built to look Egyptian, and as a nod to this, there are hieroglyphs on the glass around the space. The building overlooks the river and has stunning views, I must admit it looks like a rather nice place to be in terms of a workspace. On the top floor, we were treated to a glass of champagne, where we met John Franks the owner and founder of the business, who thanked us all for being there and mentioned that they wanted to show us something new they had been working on.

NEW PROJECTS

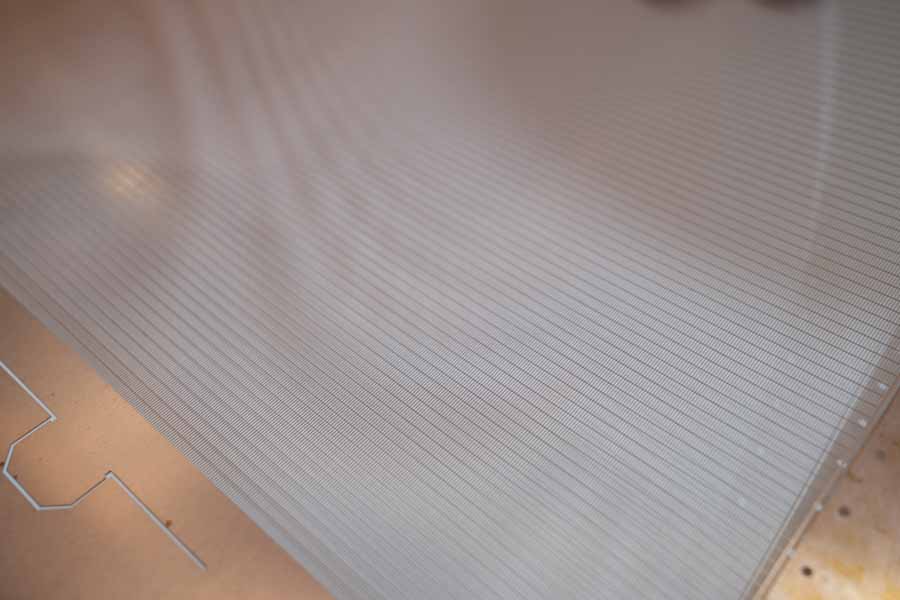

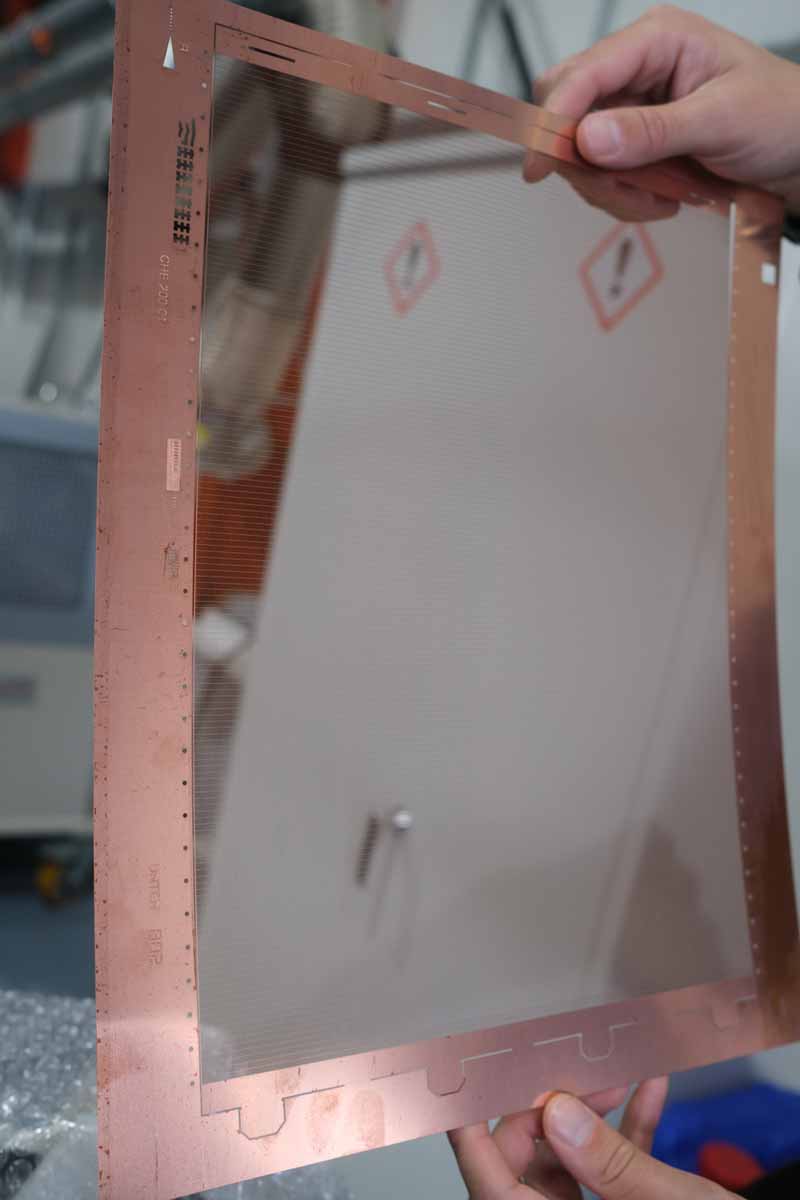

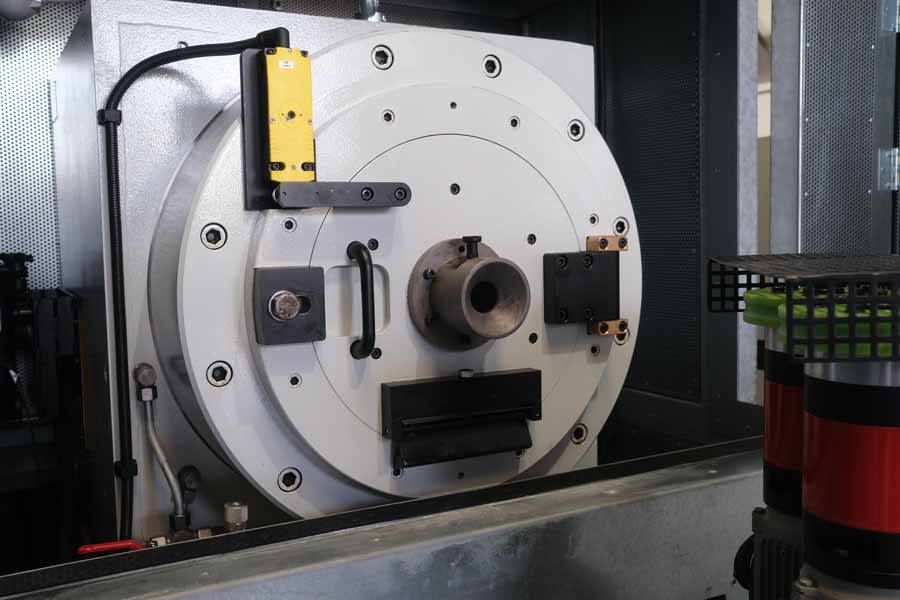

Which leads us to being driven down the road to a very secret Unit 9 – and some mad-looking machinery. Now, this setup is all for a brand-new venture that Chord Electronics are funding and running, and it has to do with carbon nanotubes and their conductivity in cables. It is all very sci-fi, however the gist of it is, as Chord explained, they use a copper base that they make cutouts to grow/deposit carbon nanotubes on, these are made in such a way that they can control the direction of the nanotubes and thus create a cable that is many times more conductive than standard copper. This allows for more data to be sent in a smaller cable, or for lower losses in terms of electric delivery, and can have wide-ranging applications (including potentially HiFi, especially in power transformers, reducing their size whilst increasing efficiency). So, this is something that we might not have expected and it will be interesting to see where this goes. Chord have an incredible team working on this project with patents being submitted and some granted already.

After that, we went for a lovely local pub lunch, which was a great way to round out this excellent visit. A huge thank you to the team at Chord Electronics and Dan George for organising this visit and inviting us along.

Oscar Stewart